有时我们想引用其他网站的资源(图片,视频等),明明在其网站上可用,而我们发送请求时却得到了403错误,访问被拒绝,很可能就是该网站对这些资源文件设置了防盗链,下面我们聊聊其防盗的原理以及破解方法。

目录

名词

防盗链

- 其效果顾名思义,就是希望阻拦其他网站来使用自己的资源文件,因为这种资源引用往往对于原本的网站来说没有收益,却还要承担流量,嫁衣了属于是。因此我们可以加一些判断,当请求不是自己允许的网站发来的时候,就拒绝。

- 而这个判断依据大多就是Http请求头中的Referer属性

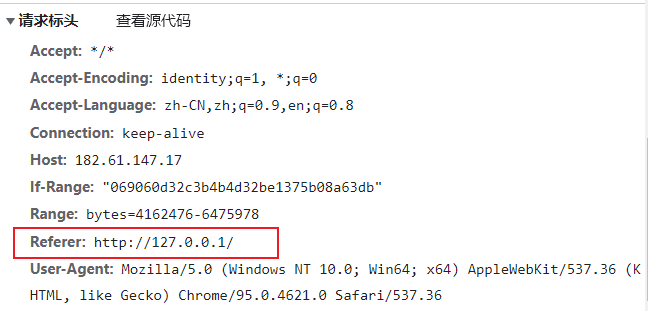

- 下面是我在http://127.0.0.1中搭建的网站发出的请求的请求头

- 可以看到,它的Referer属性值其实就是我的网址

Referer

- 当浏览器发送请求时,一般会带上Referer,告诉服务器我是哪个页面发送过来的,服务器借此可以获得一些信息用于处理。

- 在浏览器中,我们不能自定义请求的Referer属性,它是由浏览器给请求带上的。

- 当我们在地址栏直接输入网址并回车时,会发送一个Get请求,并且其Referer属性为空

- 到这里,相信你已经发现防盗链为什么使用Referer来判断,正是因为在浏览器中,它不能被伪造。

Origin

- 在请求头中,用于指明当前请求来自于哪个站点,仅包含站点信息,不包含任何路径信息

- 服务器端也经常使用这个属性来判断是否允许请求。

- 而行为正确的浏览器,也会用这个属性判断是否允许跨域请求。

破解防盗链

- 请求的所有属性,我们实际上都可以伪造,但伪造了不允许自定义的属性后的请求放在浏览器中是发不出去。

- 如果我们是客户端(比如exe,app)而不是网页,不使用浏览器,自己发送请求则可以随意伪造。

- 对于网页,我们也是有办法的。这就需要让一个服务器来代理,网页把请求发到我们的服务器,由服务器去伪造请求,拿到我们要的资源后再返回给网页即可。

- 下面我们将从这两种情况出发,以请求b站接口示例,给出解决方法。

直接伪造请求

这个方法适用于客户端,而不适用于浏览器中的网页。

- 绝大多数编程语言(c++,java,js)都有自己热门的网络库,都应该会支持自定义请求头

- 这里我们使用js来演示,注意这里的js是运行在node环境的,而非浏览器环境

- 安装好node环境

- 新建一个文件夹

- 打开cmd,cd路径到这个文件夹内,执行npm install axios安装axios

- 在这个文件夹里面新建一个文件test.js,写入:

const axios = require(`axios`);

const getServer = (in_url, in_data, successFun, errFun) => {

axios({

method: "get",

url: in_url,

params: in_data,

headers: {

"referer":"https://www.bilibili.com/"

//"referer":"https://127.0.0.1/" //你可以尝试使用这一句替换上面那句,请求将被拒绝

}

}).then(function (res) {

console.log(res.data);

if (typeof (successFun) != 'undefined') {

successFun(res);

}

console.log("--- 请求成功 ---");

}).catch(function (err) {

console.log(err);

if (typeof (errFun) != 'undefined') {

errFun(err);

}

console.log("--- 请求失败 ---");

})

}

//获取对应id的视频的下载链接

getServer(

"https://api.bilibili.com/x/player/playurl",

{

"fnval": 80,

"bvid":"BV1pT41157it",

"cid":"746904707"

});

- 这个b站接口可以获取到对应视频的下载链接

- 其referer允许置空,允许是“https://www.bilibili.com”等b站设置的允许的网站

- 你可以尝试伪造referer为"http://127.0.0.1/",模拟在浏览器中从127.0.0.1的网页中发出请求,我们就会发现请求错误,被拒绝了。

- 因此我们上面直接伪造为b站首页地址去请求是相当成功的。

代理转发

客户端,网页都适用,但一般客户端不需要由服务器代理,客户端自己可以搞定,就不需要占用服务器的带宽性能

- 这里我们的服务端使用openresty(nginx)转发请求,配置nginx的配置信息去修改referer等即可

- 示例:

server {

listen 80;

server_name localhost, 127.0.0.1;

resolver 8.8.8.8;

location / {

header_filter_by_lua_file /usr/local/openresty/lua/toBili.lua;

proxy_set_header referer 'https://www.bilibili.com/';

proxy_set_header Host $proxy_host;

proxy_set_header Origin 'https://www.bilibili.com';

if ($query_string ~* ^(.*)url=(.*)$) {

proxy_pass $2;

}

}

}- -

- 其中用到的lua脚本文件,toBili.lua:

- 这个脚本是修改响应头的3个属性,让请求允许跨域

ngx.header['Access-Control-Allow-Origin'] = '*';

ngx.header['Access-Control-Allow-Methods'] = 'get, post, options';

ngx.header['Access-Control-Allow-Headers'] = 'dnt,x-mx-reqtoken,keep-alive,user-agent,x-requested-with,if-modified-since,cache-control,content-type,authorization';- 下面我们来一步步分析配置文件和lua代码

- 显然这个配置文件是给http://127.0.0.1用的

- 第四行:resolver 8.8.8.8;

- 如果这一句不加,当转发目的地址是一个域名时,请求会出错,服务器返回502

- 在location / {} 中

- header_filter_by_lua_file即执行后面路径指向lua脚本,修改响应头的属性,让请求允许跨域。

- proxy_set_header referer 'https://www.bilibili.com/';显然就是我们的重点,修改请求头,伪造referer。后面也是伪造Host Origin。

- if ($query_string ~* ^(.*)url=(.*)$) { proxy_pass $2; }

- $query_string是请求带的所有参数

- 在if()内是正则表达式在匹配参数中名为url开始,到链接末尾的部分

- 如果匹配成功,即url参数存在,则转发到参数指定的链接

- 注意这里匹配参数不能使用nginx的语法糖$arg_url,当目标链接也带有多个参数时$arg_url只会截取一部分,导致部分参数丢失。

- 示例: http://127.0.0.1/?url=https://www.baidu.com?a=1&b=2

- 我们预期应该是通过服务器转发到url指定的链接:https://www.baidu.com?a=1&b=2

- 然而,如果使用$arg_url匹配,根据标准,匹配出来url会是https://www.baidu.com?a=1

- 因为b=2前面由符号&,因此会认为是发给127.0.0.1有两个参数:url=https://www.baidu.com?a=1和b=2

- 我们使用时就可以写 http://127.0.0.1/?url=https://www.baidu.com,这样就会转发到百度首页。

关于空referer

- 伪造空referer

- 前面我们提到,之前在浏览器敲地址后进入,其请求的referer就是空的

- 除了用服务器代理置空以外,我们还可以在html网页中配置meta标签,告诉浏览器在跳转页面时不要带上referer

- 在html的head标签内增加:

<metaname="referrer" content="never"> - 还有可以设置单个<a>标签跳转时不带上referer、使用window.open打开等操作。

- 在html的head标签内增加:

<!DOCTYPE html>

<html lang="zh">

<head>

<meta name="referrer" content="never">

</head>

<body>

</body>- 然而部分浏览器在使用上面的方法跳转下载文件时,由于其下载加速之类的功能,将会自动截取下载链接中的域名等添加为referer。

- 这么做初衷当然是好的,然而目前很多网站会使用云服务器商(如阿里云、腾讯云等)提供的对象存储、cdn等,而且这些功能提供的下载链接大部分的域名和源网站并不相同,但他们会拦截非源网站的referer,甚至有的自己的域名referer都拦截!

- 例如:

- 假设我想在我的网站提供下载B站视频,假设b站视频由cdn提供下载,且仅允许b站referer和空referer

- 我们的网站是:www.coolight.cool

- b站:www.bilibili.com

- cdn提供的某个视频的下载链接:www.cdn.com/bilibili/video/BV123456789

- 当我们使用上述有下载加速功能的浏览器时,首先在我们的网站,点击下载按钮,然后跳转到下载链接[https://www.cdn.com/bilibili/video/BV123456789],此时应是空referer,但下载加速功能自动截取下载链接的域名部分作为referer[https://www.cdn.com/],然后发送请求,而cdn发现请求referer即非空,也非b站,则会返回403拒绝请求。

- 最死的还是有些浏览器,先发第一个请求获取目标下载文件的大小等信息,这个请求确实是没有referer,所以成功得到文件信息,然后开始分块下载,这个时候又带上自动截取的referer,然后就导致后面下载失败。

- 假设我想在我的网站提供下载B站视频,假设b站视频由cdn提供下载,且仅允许b站referer和空referer

- 解决办法:

- 提示建议用户更换浏览器

- 提示建议用户关闭浏览器的下载加速之类的功能

- 更换使用服务器代理

摸索过程记录

- 难点显然是在给web的代理转发上,一开始懂的也很少,还精准踩了很多百度上没有的坑。

- 首先是proxy_set_header referer 'https://www.bilibili.com/';

- 一开始就写了这句,然后就直接proxy_pass $arg_url转发,结果就一直返回502错误。

- 百度才发现需要加一句resolver 8.8.8.8

- 然后先是尝试了转发到百度,也就是写 http://127.0.0.1/?url=https://www.baidu.com,正常可用!

- 但在尝试b站的接口的时候,有的接口可以,有的却不行,这个时候我就开始疑惑

- 后来直接把proxy_pass的目标路径改成一个固定链接 https://api.bilibili.com/x/player/pagelist?bvid=BV1pT41157it,居然成功了,那显然问题就是这个$arg_url

- 然后就发现了它在目标地址携带多个参数时截取后会丢失部分参数

- 修改完这个问题后,在浏览器地址栏直接测试都是成功的了

- 接下来就是把这个方法用在项目里,出现跨域问题

- 配置跨域

- 自然而然地百度后直接修改配置文件,增加三句:

add_header Access-Control-Allow-Origin '*';

add_header Access-Control-Allow-Methods 'POST,OPTIONS,GET';

add_header Access-Control-Allow-Headers 'DNT,X-Mx-ReqToken,Keep-Alive,User-Agent,X-Requested-With,If-Modified-Since,Cache-Control,Content-Type,Authorization';- -

- 但是后来发现有些接口它自己会添加Access-Control-Allow-Origin,然后我配置了nginx也添加了这个,导致这个的值出现多次,浏览器开始报错

- 于是寻找方法,希望可以判断是否存在,没有则添加,有则修改

- 于是找到了openresty,可以认为它是 nginx + 插件

- 然后在openresty配置了lua脚本去修改。

思考

上面的示例中,我们在使用时,只能也必须传入一个参数 url,那有没有办法传递更多参数呢?

- 1: 可以将参数 url 的值进行 url编码,避免歧义,然后在nginx中截取出参数url的值后进行 url解码后再转发请求即可。

- 2: 链接的路径部分我们还可以动动手脚。

Оборудование актовых залов http://oborudovanija-dlja-aktovyh-zalov.ru .

музыкальное оборудование для актового зала http://www.oborudovanija-dlja-aktovyh-zalov.ru/ .

RGBET trang chủ

RGBET trang chủ với hệ thống game nhà cái đỉnh cao – Nhà cái uy tín số 1 Việt Nam trong lĩnh vực cờ bạc online

RG trang chủ, RG RICH GAME, Nhà Cái RG

RGBET Trang Chủ Và Câu Chuyện Thương Hiệu

Ra đời vào năm 2010 tại Đài Loan, RGBET nhanh chóng trở thành một trang cá cược chất lượng hàng đầu khu vực Châu Á. Nhà cái được cấp phép hoạt động hợp pháp bởi công ty giải trí trực tuyến hợp pháp được ủy quyền và giám sát theo giấy phép Malta của Châu Âu – MGA. Và chịu sự giám sát chặt chẽ của tổ chức PAGCOR và BIV.

RGBET trang chủ cung cấp cho người chơi đa dạng các thể loại cược đặc sắc như: thể thao, đá gà, xổ số, nổ hũ, casino trực tuyến. Dịch vụ CSKH luôn hoạt động 24/7. Với chứng chỉ công nghệ GEOTRUST, nhà cái đảm bảo an toàn cho mọi giao dịch của khách hàng. APP RG thiết kế tối ưu giải quyết mọi vấn đề của người dùng IOS và Android.

Là một nhà cái đến từ đất nước công nghệ, nhà cái luôn không ngừng xây dựng và nâng cấp hệ thống game và dịch vụ hoàn hảo. Mọi giao dịch nạp rút được tự động hoá cho phép người chơi hoàn tất giao dịch chỉ với 2 phút vô cùng nhanh chóng

RGBET Lớn Nhất Uy Tín Nhất – Giá Trị Cốt Lõi

Nhà Cái RG Và Mục Tiêu Thương Hiệu

Giá trị cốt lõi mà RGBET mong muốn hướng đến đó chính là không ngừng hoàn thiện để đem đến một hệ thống chất lượng, công bằng và an toàn. Nâng cao sự hài lòng của người chơi, đẩy mạnh hoạt động chống gian lận và lừa đảo. RG luôn cung cấp hệ thống kèo nhà cái đặc sắc, cùng các sự kiện – giải đấu hàng đầu và tỷ lệ cược cạnh tranh đáp ứng mọi nhu cầu khách hàng.

Thương hiệu cá cược RGBET cam kết đem lại cho người chơi môi trường cá cược công bằng, văn minh và lành mạnh. Đây là nguồn động lực to lớn giúp nhà cái thực tế hóa các hoạt động của mình.

RGBET Có Tầm Nhìn Và Sứ Mệnh

Đổi mới và sáng tạo là yếu tố cốt lõi giúp đạt được mục tiêu dưới sự chuyển mình mạnh mẽ của công nghệ. Tầm nhìn và sứ mệnh của RGBET là luôn tìm tòi những điều mới lạ, đột phá mạnh mẽ, vượt khỏi giới hạn bản thân, đương đầu với thử thách để đem đến cho khách hàng sản phẩm hoàn thiện nhất.

Chúng tôi luôn sẵn sàng tiếp thu ý kiến và nâng cao bản thân mỗi ngày để tạo ra sân chơi bổ ích, uy tín và chuyên nghiệp cho người chơi. Để có thể trở thành nhà cái phù hợp với mọi khách hàng.

Khái Niệm Giá Trị Cốt Lõi Nhà Cái RGBET

Giá trị cốt lõi của nhà cái RG luôn gắn kết chặt chẽ với nhau giữa 5 khái niệm: Chính trực, chuyên nghiệp, an toàn, đổi mới, công nghệ.

Chính Trực

Mọi quy luật, cách thức của trò chơi đều được nhà cái cung cấp công khai, minh bạch và chi tiết. Mỗi tựa game hoạt động đều phải chịu sự giám sát kỹ lưỡng bởi các cơ quan tổ chức có tiếng về sự an toàn và minh bạch của nó.

Chuyên Nghiệp

Các hoạt động tại RGBET trang chủ luôn đề cao sự chuyên nghiệp lên hàng đầu. Từ giao diện đến chất lượng sản phẩm luôn được trau chuốt tỉ mỉ từng chi tiết. Thế giới giải trí được xây dựng theo văn hóa Châu Á, phù hợp với đại đa số thị phần khách Việt.

An Toàn

RG lớn nhất uy tín nhất luôn ưu tiên sử dụng công nghệ mã hóa hiện đại nhất để đảm bảo an toàn, riêng tư cho toàn bộ thông tin của người chơi. Đơn vị cam kết nói không với hành vi gian lận và mua bán, trao đổi thông tin cá nhân bất hợp pháp.

Đổi Mới

Nhà cái luôn theo dõi và bắt kịp xu hướng thời đại, liên tục bổ sung các sản phẩm mới, phương thức cá cược mới và các ưu đãi độc lạ, mang đến những trải nghiệm thú vị cho người chơi.

Công Nghệ

RGBET trang chủ tập trung xây dựng một giao diện game sắc nét, sống động cùng tốc độ tải nhanh chóng. Ứng dụng RGBET giải nén ít dung lượng phù hợp với mọi hệ điều hành và cấu hình, tăng khả năng sử dụng của khách hàng.

RGBET Khẳng Định Giá Trị Thương Hiệu

Hoạt động hợp pháp với đầy đủ giấy phép, chứng chỉ an toàn đạt tiêu chuẩn quốc tế

Hệ thống game đa màu sắc, đáp ứng được mọi nhu cầu người chơi

Chính sách bảo mật RG hiện đại và đảm bảo an toàn cho người chơi cá cược

Bắt tay hợp tác với nhiều đơn vị phát hành game uy tín, chất lượng thế giới

Giao dịch nạp rút RG cấp tốc, nhanh gọn, bảo mật an toàn

Kèo nhà cái đa dạng với bảng tỷ lệ kèo cao, hấp dẫn

Dịch Vụ RGBET Casino Online

Dịch vụ khách hàng

Đội ngũ CSKH RGBET luôn hoạt động thường trực 24/7. Nhân viên được đào tạo chuyên sâu luôn giải đáp tất cả các khó khăn của người chơi về các vấn đề tài khoản, khuyến mãi, giao dịch một cách nhanh chóng và chuẩn xác. Hạn chế tối đa làm ảnh hưởng đến quá trình trải nghiệm của khách hàng.

Đa dạng trò chơi

Với sự nhạy bén trong cập nhật xu thế, nhà cái RGBET đã dành nhiều thời gian phân tích nhu cầu khách hàng, đem đến một kho tàng game chất lượng với đa dạng thể loại từ RG casino online, thể thao, nổ hũ, game bài, đá gà, xổ số.

Khuyến mãi hấp dẫn

RGBET trang chủ liên tục cập nhật và thay đổi các sự kiện ưu đãi đầy hấp dẫn và độc đáo. Mọi thành viên bất kể là người chơi mới, người chơi cũ hay hội viên VIP đều có cơ hội được hưởng ưu đãi đặc biệt từ nhà cái.

Giao dịch linh hoạt, tốc độ

Thương hiệu RGBET luôn chú tâm đến hệ thống giao dịch. Nhà cái cung cấp dịch vụ nạp rút nhanh chóng với đa dạng phương thức như thẻ cào, ví điện tử, ngân hàng điện tử, ngân hàng trực tiếp. Mọi hoạt động đều được bảo mật tuyệt đối bởi công nghệ mã hóa tiên tiến.

App cá độ RGBET

App cá độ RGBET là một ứng dụng cho phép người chơi đăng nhập RG nhanh chóng, đồng thời các thao tác đăng ký RG trên app cũng được tối ưu và trở nên đơn giản hơn. Tham gia cá cược RG bằng app cá độ, người chơi sẽ có 1 trải nghiệm cá cược tuyệt vời và thú vị.

RGBET Có Chứng Nhận Cá Cược Quốc Tế

Nhà cái RGBET hoạt động hợp pháp dưới sự cấp phép của hai tổ chức thế giới là PAGCOR và MGA, tính minh bạch và công bằng luôn được giám sát gắt gao bởi BIV. Khi tham gia cược tại đây, người chơi sẽ được đảm bảo quyền và lợi ích hợp pháp của mình.

Việc sở hữu các chứng nhận quốc tế còn cho thấy nguồn tài chính ổn định, dồi dào của RGBET. Điều này cho thấy việc một nhà cái được công nhận bởi các cơ quan quốc tế không phải là một chuyện dễ.

Theo quy định nhà cái RGBET, chỉ người chơi từ đủ 18 tuổi trở lên mới có thể tham gia cá cược tại RGBET

MGA (Malta Gaming Authority)

Tổ chức MGA đảm bảo tính vẹn toàn và ổn định của các trò chơi. Có các chính sách bảo vệ nguồn tài chính và quyền lợi của người chơi. Chứng nhận một nhà cái hoạt động có đầy đủ pháp lý, tuân thủ nghiêm chỉnh luật cờ bạc.

Chứng nhận Quần đảo Virgin Vương quốc Anh (BIV)

Tổ chứng chứng nhận nhà cái có đầy đủ tài chính để hoạt động kinh doanh cá cược. Với nguồn ngân sách dồi dào, ổn định nhà cái bảo đảm tính thanh khoản cho người chơi, mọi quyền lợi sẽ không bị xâm phạm.

Giấy Phép PAGCOR

Tổ chức cấp giấy phép cho nhà cái hoạt động đạt chuẩn theo tiêu chuẩn quốc tế. Cho phép nhà cái tổ chức cá cược một cách hợp pháp, không bị rào cản. Có chính sách ngăn chặn mọi trò chơi có dấu hiệu lừa đảo, duy trì sự minh bạch, công bằng.

Nhà Cái RGBET Phát Triển Công Nghệ

Nhà cái RGBET hỗ trợ trên nhiều thiết bị : IOS, Android, APP, WEB, Html5

RG và Trách Nhiệm Xã Hội

RGBET RichGame không đơn thuần là một trang cá cược giải trí mà nhà cái còn thể hiện rõ tính trách nhiệm xã hội của mình. Đơn vị luôn mong muốn người chơi tham gia cá cược phải có trách nhiệm với bản thân, gia đình và cả xã hội. Mọi hoạt động diễn ra tại RGBET trang chủ nói riêng hay bất kỳ trang web khác, người chơi phải thật sự bình tĩnh và lý trí, đừng để bản thân rơi vào “cạm bẫy của cờ bạc”.

RGBET RichGame với chính sách nghiêm cấm mọi hành vi xâm phạm thông tin cá nhân và gian lận nhằm tạo ra một môi trường cá cược công bằng, lành mạnh. Nhà cái khuyến cáo mọi cá nhân chưa đủ 18 tuổi không nên đăng ký RG và tham gia vào bất kỳ hoạt động cá cược nào.

rgbet a9b1294

RGBET trang chủ

RGBET trang chủ với hệ thống game nhà cái đỉnh cao – Nhà cái uy tín số 1 Việt Nam trong lĩnh vực cờ bạc online

RG trang chủ, RG RICH GAME, Nhà Cái RG

RGBET Trang Chủ Và Câu Chuyện Thương Hiệu

Ra đời vào năm 2010 tại Đài Loan, RGBET nhanh chóng trở thành một trang cá cược chất lượng hàng đầu khu vực Châu Á. Nhà cái được cấp phép hoạt động hợp pháp bởi công ty giải trí trực tuyến hợp pháp được ủy quyền và giám sát theo giấy phép Malta của Châu Âu – MGA. Và chịu sự giám sát chặt chẽ của tổ chức PAGCOR và BIV.

RGBET trang chủ cung cấp cho người chơi đa dạng các thể loại cược đặc sắc như: thể thao, đá gà, xổ số, nổ hũ, casino trực tuyến. Dịch vụ CSKH luôn hoạt động 24/7. Với chứng chỉ công nghệ GEOTRUST, nhà cái đảm bảo an toàn cho mọi giao dịch của khách hàng. APP RG thiết kế tối ưu giải quyết mọi vấn đề của người dùng IOS và Android.

Là một nhà cái đến từ đất nước công nghệ, nhà cái luôn không ngừng xây dựng và nâng cấp hệ thống game và dịch vụ hoàn hảo. Mọi giao dịch nạp rút được tự động hoá cho phép người chơi hoàn tất giao dịch chỉ với 2 phút vô cùng nhanh chóng

RGBET Lớn Nhất Uy Tín Nhất – Giá Trị Cốt Lõi

Nhà Cái RG Và Mục Tiêu Thương Hiệu

Giá trị cốt lõi mà RGBET mong muốn hướng đến đó chính là không ngừng hoàn thiện để đem đến một hệ thống chất lượng, công bằng và an toàn. Nâng cao sự hài lòng của người chơi, đẩy mạnh hoạt động chống gian lận và lừa đảo. RG luôn cung cấp hệ thống kèo nhà cái đặc sắc, cùng các sự kiện – giải đấu hàng đầu và tỷ lệ cược cạnh tranh đáp ứng mọi nhu cầu khách hàng.

Thương hiệu cá cược RGBET cam kết đem lại cho người chơi môi trường cá cược công bằng, văn minh và lành mạnh. Đây là nguồn động lực to lớn giúp nhà cái thực tế hóa các hoạt động của mình.

RGBET Có Tầm Nhìn Và Sứ Mệnh

Đổi mới và sáng tạo là yếu tố cốt lõi giúp đạt được mục tiêu dưới sự chuyển mình mạnh mẽ của công nghệ. Tầm nhìn và sứ mệnh của RGBET là luôn tìm tòi những điều mới lạ, đột phá mạnh mẽ, vượt khỏi giới hạn bản thân, đương đầu với thử thách để đem đến cho khách hàng sản phẩm hoàn thiện nhất.

Chúng tôi luôn sẵn sàng tiếp thu ý kiến và nâng cao bản thân mỗi ngày để tạo ra sân chơi bổ ích, uy tín và chuyên nghiệp cho người chơi. Để có thể trở thành nhà cái phù hợp với mọi khách hàng.

Khái Niệm Giá Trị Cốt Lõi Nhà Cái RGBET

Giá trị cốt lõi của nhà cái RG luôn gắn kết chặt chẽ với nhau giữa 5 khái niệm: Chính trực, chuyên nghiệp, an toàn, đổi mới, công nghệ.

Chính Trực

Mọi quy luật, cách thức của trò chơi đều được nhà cái cung cấp công khai, minh bạch và chi tiết. Mỗi tựa game hoạt động đều phải chịu sự giám sát kỹ lưỡng bởi các cơ quan tổ chức có tiếng về sự an toàn và minh bạch của nó.

Chuyên Nghiệp

Các hoạt động tại RGBET trang chủ luôn đề cao sự chuyên nghiệp lên hàng đầu. Từ giao diện đến chất lượng sản phẩm luôn được trau chuốt tỉ mỉ từng chi tiết. Thế giới giải trí được xây dựng theo văn hóa Châu Á, phù hợp với đại đa số thị phần khách Việt.

An Toàn

RG lớn nhất uy tín nhất luôn ưu tiên sử dụng công nghệ mã hóa hiện đại nhất để đảm bảo an toàn, riêng tư cho toàn bộ thông tin của người chơi. Đơn vị cam kết nói không với hành vi gian lận và mua bán, trao đổi thông tin cá nhân bất hợp pháp.

Đổi Mới

Nhà cái luôn theo dõi và bắt kịp xu hướng thời đại, liên tục bổ sung các sản phẩm mới, phương thức cá cược mới và các ưu đãi độc lạ, mang đến những trải nghiệm thú vị cho người chơi.

Công Nghệ

RGBET trang chủ tập trung xây dựng một giao diện game sắc nét, sống động cùng tốc độ tải nhanh chóng. Ứng dụng RGBET giải nén ít dung lượng phù hợp với mọi hệ điều hành và cấu hình, tăng khả năng sử dụng của khách hàng.

RGBET Khẳng Định Giá Trị Thương Hiệu

Hoạt động hợp pháp với đầy đủ giấy phép, chứng chỉ an toàn đạt tiêu chuẩn quốc tế

Hệ thống game đa màu sắc, đáp ứng được mọi nhu cầu người chơi

Chính sách bảo mật RG hiện đại và đảm bảo an toàn cho người chơi cá cược

Bắt tay hợp tác với nhiều đơn vị phát hành game uy tín, chất lượng thế giới

Giao dịch nạp rút RG cấp tốc, nhanh gọn, bảo mật an toàn

Kèo nhà cái đa dạng với bảng tỷ lệ kèo cao, hấp dẫn

Dịch Vụ RGBET Casino Online

Dịch vụ khách hàng

Đội ngũ CSKH RGBET luôn hoạt động thường trực 24/7. Nhân viên được đào tạo chuyên sâu luôn giải đáp tất cả các khó khăn của người chơi về các vấn đề tài khoản, khuyến mãi, giao dịch một cách nhanh chóng và chuẩn xác. Hạn chế tối đa làm ảnh hưởng đến quá trình trải nghiệm của khách hàng.

Đa dạng trò chơi

Với sự nhạy bén trong cập nhật xu thế, nhà cái RGBET đã dành nhiều thời gian phân tích nhu cầu khách hàng, đem đến một kho tàng game chất lượng với đa dạng thể loại từ RG casino online, thể thao, nổ hũ, game bài, đá gà, xổ số.

Khuyến mãi hấp dẫn

RGBET trang chủ liên tục cập nhật và thay đổi các sự kiện ưu đãi đầy hấp dẫn và độc đáo. Mọi thành viên bất kể là người chơi mới, người chơi cũ hay hội viên VIP đều có cơ hội được hưởng ưu đãi đặc biệt từ nhà cái.

Giao dịch linh hoạt, tốc độ

Thương hiệu RGBET luôn chú tâm đến hệ thống giao dịch. Nhà cái cung cấp dịch vụ nạp rút nhanh chóng với đa dạng phương thức như thẻ cào, ví điện tử, ngân hàng điện tử, ngân hàng trực tiếp. Mọi hoạt động đều được bảo mật tuyệt đối bởi công nghệ mã hóa tiên tiến.

App cá độ RGBET

App cá độ RGBET là một ứng dụng cho phép người chơi đăng nhập RG nhanh chóng, đồng thời các thao tác đăng ký RG trên app cũng được tối ưu và trở nên đơn giản hơn. Tham gia cá cược RG bằng app cá độ, người chơi sẽ có 1 trải nghiệm cá cược tuyệt vời và thú vị.

RGBET Có Chứng Nhận Cá Cược Quốc Tế

Nhà cái RGBET hoạt động hợp pháp dưới sự cấp phép của hai tổ chức thế giới là PAGCOR và MGA, tính minh bạch và công bằng luôn được giám sát gắt gao bởi BIV. Khi tham gia cược tại đây, người chơi sẽ được đảm bảo quyền và lợi ích hợp pháp của mình.

Việc sở hữu các chứng nhận quốc tế còn cho thấy nguồn tài chính ổn định, dồi dào của RGBET. Điều này cho thấy việc một nhà cái được công nhận bởi các cơ quan quốc tế không phải là một chuyện dễ.

Theo quy định nhà cái RGBET, chỉ người chơi từ đủ 18 tuổi trở lên mới có thể tham gia cá cược tại RGBET

MGA (Malta Gaming Authority)

Tổ chức MGA đảm bảo tính vẹn toàn và ổn định của các trò chơi. Có các chính sách bảo vệ nguồn tài chính và quyền lợi của người chơi. Chứng nhận một nhà cái hoạt động có đầy đủ pháp lý, tuân thủ nghiêm chỉnh luật cờ bạc.

Chứng nhận Quần đảo Virgin Vương quốc Anh (BIV)

Tổ chứng chứng nhận nhà cái có đầy đủ tài chính để hoạt động kinh doanh cá cược. Với nguồn ngân sách dồi dào, ổn định nhà cái bảo đảm tính thanh khoản cho người chơi, mọi quyền lợi sẽ không bị xâm phạm.

Giấy Phép PAGCOR

Tổ chức cấp giấy phép cho nhà cái hoạt động đạt chuẩn theo tiêu chuẩn quốc tế. Cho phép nhà cái tổ chức cá cược một cách hợp pháp, không bị rào cản. Có chính sách ngăn chặn mọi trò chơi có dấu hiệu lừa đảo, duy trì sự minh bạch, công bằng.

Nhà Cái RGBET Phát Triển Công Nghệ

Nhà cái RGBET hỗ trợ trên nhiều thiết bị : IOS, Android, APP, WEB, Html5

RG và Trách Nhiệm Xã Hội

RGBET RichGame không đơn thuần là một trang cá cược giải trí mà nhà cái còn thể hiện rõ tính trách nhiệm xã hội của mình. Đơn vị luôn mong muốn người chơi tham gia cá cược phải có trách nhiệm với bản thân, gia đình và cả xã hội. Mọi hoạt động diễn ra tại RGBET trang chủ nói riêng hay bất kỳ trang web khác, người chơi phải thật sự bình tĩnh và lý trí, đừng để bản thân rơi vào “cạm bẫy của cờ bạc”.

RGBET RichGame với chính sách nghiêm cấm mọi hành vi xâm phạm thông tin cá nhân và gian lận nhằm tạo ra một môi trường cá cược công bằng, lành mạnh. Nhà cái khuyến cáo mọi cá nhân chưa đủ 18 tuổi không nên đăng ký RG và tham gia vào bất kỳ hoạt động cá cược nào.

rgbet 9d8952e

accutane generic

comのドールコレクションは非常に多様で、さまざまなニーズに応えています.セックス ドール各ドールのページには詳細な説明と高解像度の画像があり、商品の特長をしっかりと把握することができます.

which added great depth to your analysis.This article is a treasure trove of valuable information for anyone interested in [specific topic].ラブドール

световое оборудование для актового зала световое оборудование для актового зала .

световое оборудование для актового зала световое оборудование для актового зала .

видеостены videosteny-dlja-sozdanija-jekranov.ru .

видеостена оборудование видеостена оборудование .

Останні новини світу https://uamc.com.ua про Україну від порталу новин Ukraine Today

buy lyrica usa

Останні новини https://thingshistory.com зовнішньої та внутрішньої політики в країні та світі.

Головні новини https://status.net.ua сьогодні, найсвіжіші та останні новини України онлайн

Корисні та цікаві статті https://sevsovet.com.ua про здоров’я, дозвілля, кар’єру.

оборудование для актового зала оборудование для актового зала .

Новини, останні події https://prp.org.ua в Україні та світі, новини політики, бізнесу та економіки, законодавства