目录

要求

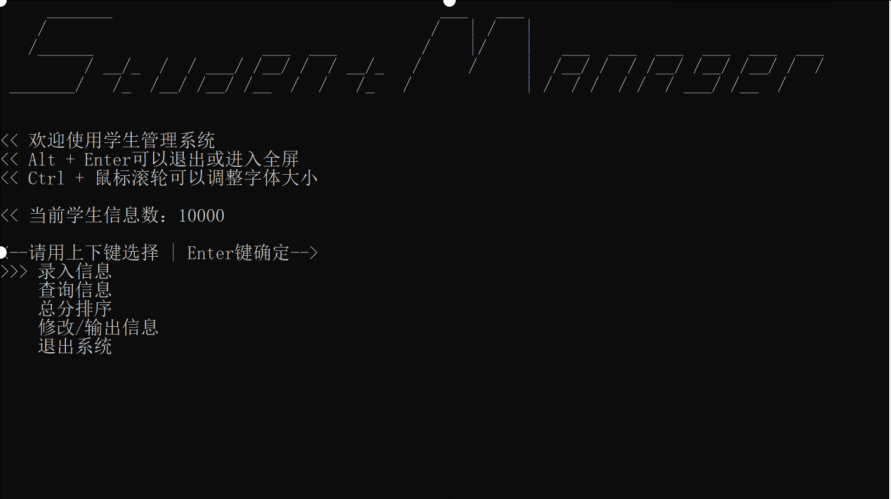

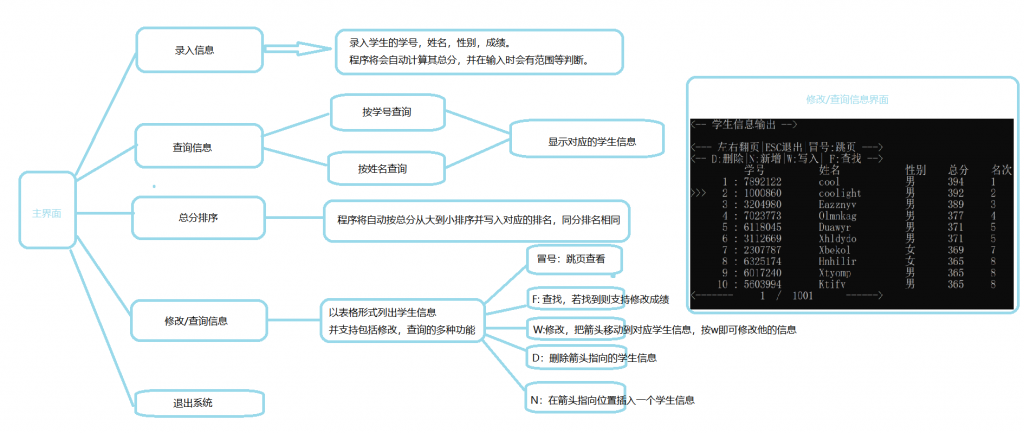

- 请设计一个学生成绩管理系统。学生信息包括学号、姓名、性别、英语、数学、程序设计、数据结构、总分、名次等内容。请实现如下功能:

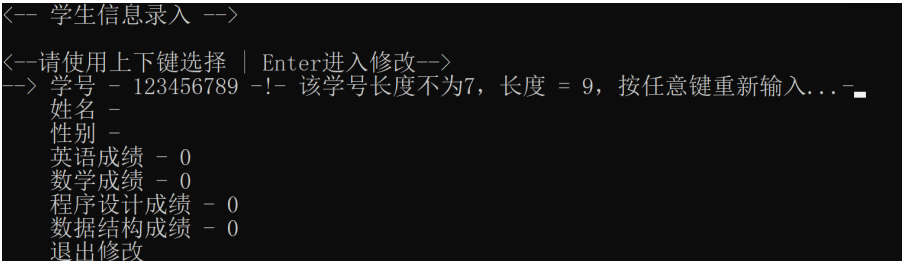

- 学生信息的录入(并能够检查学号重复者、成绩不超过100分检查,计算总分);

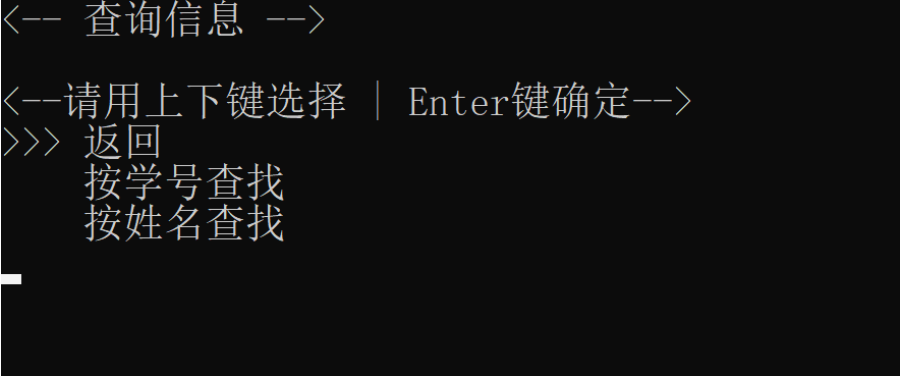

- 学生信息的查询(可以按照学号和姓名两种方式查询);

- 学生信息的修改(一律按照学号对应修改,仅对四门课程成绩修改);

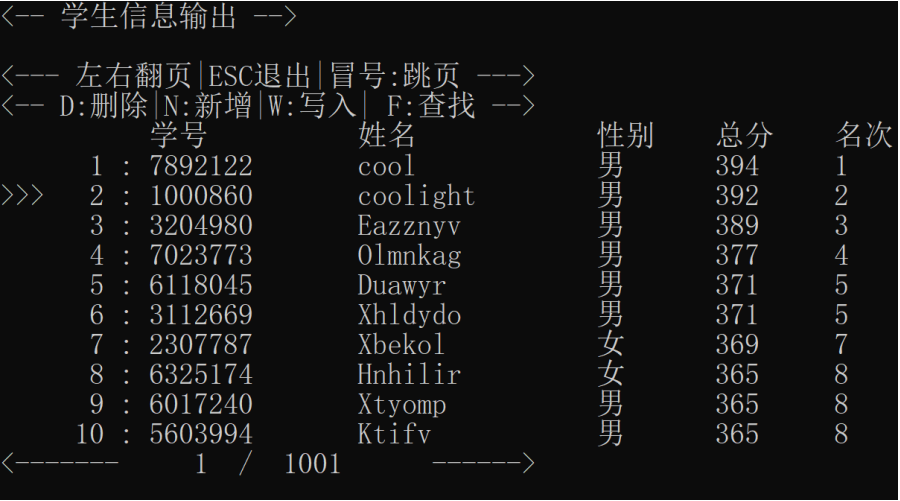

- 学生总分的排序(要求稳定排序,有相同分数时按照并列名次处理);

- 学生信息的输出;

- 退出管理系统;

效果图

Gif 动图

各界面图

源代码下载

若以下显示需要登录,请刷新页面或点击此处下载。

流程图

思路与算法

- 数据结构

- 双向链表(使用STL的list)

- 算法

- 插入:尾插法(list::push_back())

- 排序:二路归并(其实最好是采用基数排序)

- 查找:顺序查找

注意

- 本例中使用了SLT的list,但查找,排序算法是自己写的。其实用我自己的双向队列后实现查找排序会简单很多,但由于需要使用到coolfun中的一些控制台界面函数(coolfun::switch_show_change),因此骑虎难下。

- 本例中是使用了包含大部分自己写的函数的函数库coolfun,将会在后续文章中介绍它。

ciprofloxacin generic price: buy cipro online – buy cipro without rx

You’re so cool! I do not think I’ve truly read something like this before. So great to find another person with some original thoughts on this subject. Seriously.. thanks for starting this up. This web site is one thing that is needed on the internet, someone with a little originality.

amoxicillin 775 mg: can we buy amoxcillin 500mg on ebay without prescription – amoxicillin 500 mg cost

Everything is very open with a very clear clarification of the issues. It was really informative. Your site is extremely helpful. Thank you for sharing!

The very next time I read a blog, I hope that it doesn’t fail me as much as this one. After all, Yes, it was my choice to read, however I actually believed you’d have something useful to talk about. All I hear is a bunch of whining about something that you could fix if you weren’t too busy searching for attention.

Hi, I do believe this is a great blog. I stumbledupon it 😉 I will come back yet again since i have saved as a favorite it. Money and freedom is the greatest way to change, may you be rich and continue to help others.

This is a topic which is close to my heart… Cheers! Exactly where are your contact details though?

When I initially commented I seem to have clicked on the -Notify me when new comments are added- checkbox and now every time a comment is added I get four emails with the exact same comment. Perhaps there is an easy method you can remove me from that service? Many thanks.

May I just say what a relief to discover an individual who truly knows what they’re talking about online. You certainly know how to bring a problem to light and make it important. More and more people really need to read this and understand this side of your story. I was surprised you’re not more popular because you definitely have the gift.

Новини України https://kiev-online.com.ua останні події в Україні та світі сьогодні, новини України за минулий день онлайн

This is a really good tip particularly to those new to the blogosphere. Brief but very accurate information… Thank you for sharing this one. A must read post.

I would like to thank you for the efforts you’ve put in penning this blog. I really hope to check out the same high-grade content by you in the future as well. In truth, your creative writing abilities has inspired me to get my very own website now 😉

Hello, I do think your web site may be having browser compatibility issues. Whenever I look at your site in Safari, it looks fine however, if opening in IE, it’s got some overlapping issues. I simply wanted to give you a quick heads up! Aside from that, wonderful blog.

Oh my goodness! Amazing article dude! Thanks, However I am encountering difficulties with your RSS. I don’t know the reason why I cannot subscribe to it. Is there anyone else getting the same RSS issues? Anybody who knows the solution will you kindly respond? Thanx!!

Good post. I learn something new and challenging on sites I stumbleupon on a daily basis. It’s always interesting to read content from other writers and practice a little something from their sites.

Nice post. I learn something new and challenging on blogs I stumbleupon everyday. It will always be interesting to read articles from other writers and practice something from other websites.

May I simply just say what a relief to discover somebody that truly knows what they are talking about on the net. You certainly know how to bring a problem to light and make it important. More people ought to check this out and understand this side of the story. I was surprised that you are not more popular since you most certainly have the gift.

Having read this I thought it was extremely informative. I appreciate you taking the time and effort to put this information together. I once again find myself personally spending way too much time both reading and leaving comments. But so what, it was still worth it.